High resolution Non-contact 3D Measurement System

STIL Optical Pen

Feature /

Measurement Principle /

Application /

Specification

Feature

- High resolution, High Precision

- Any type of sample (Transparent/Opaque, Polished/Rough)

- All materials (Metal, Glass, Semiconductor, Plastic...)

- No preparation of the sample required

- 2 standard measuring modes: Distance and Thickness

- Large choice of Optical Pens

- Free software tools including SDK

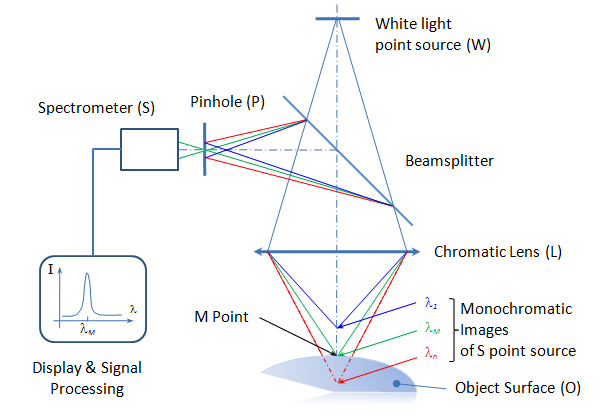

Measurement Principle(Chromatic Confocal Sensing)

Chromatic Confocal sensing (STIL patent) was invented in 1995 and has since been worldwide acknowledged as an accurate and reliable technique for non-contact distance and thickness measurement.

It is one of the very few non-contact techniques for 3D metrology recommended by the ISO 25178 international standard.

A chromatic lens L generates the image of a point white-light source W as a continuum of monochromatic images located on the optical axis (“Chromatic coding”).

A sample is located inside the color-coded segment and its surface scatters the incident light beam.

The backscattered light passes through the chromatic lens L in the opposite direction, and arrives at a pinhole P which filters out all wavelengths except a single wavelength, λM.

The collected light is analyzed by a spectrometer S. The sample position (point M) is directly related to the detected wavelength.

Application

|

|

|

|

|

| Roughness | In-line Control | Thickness | Autofocus | Micortopography |

|

|

| Lens Form Measurement(Spherical,Aspherical) |